The Cooperative’s modern privately-owned production facilities include parent stock farms, hatcheries, a feed mill, a slaughterhouse, a cutting section for anatomical cuts, processing and packaging facilities, a refrigeration and freezing complex, a by-products processing plant, a vehicle maintenance workshop, and a biological treatment unit.

With the aim of further expanding its activities and benefiting customers, consumers, shareholders, and employees, in 2008, the Cooperative successfully completed an ambitious development and investment program worth €17,000,000. This program created new state-of-the-art conditions and processes for chicken product production in Greece and Europe, ensuring higher standards, methods, practices, and operations at every stage of production and development.

The completion of this development program enabled the Cooperative to expand and modernize its slaughterhouse, refrigeration, and freezing facilities, as well as to implement an ultra-modern three-stage air-chilling system.

At the same time, this investment provided the necessary conditions for environmental protection through the construction of an inert waste incineration unit for energy production.

processing –

packaging

The first stage in the production process after cooling is whole chicken packaging, where a portion of the birds is packed in group packaging.

Those that are not used in this stage move on to cutting, processing, and final packaging. This sorting process is carried out automatically.

All processing areas comply with Greek and European legislation and follow good hygiene practices to ensure food safety.

The room temperature does not exceed 10°C. Throughout processing, the chicken remains below 4°C to ensure the cold chain remains intact. Employees receive regular hygiene and food safety training.

distribution

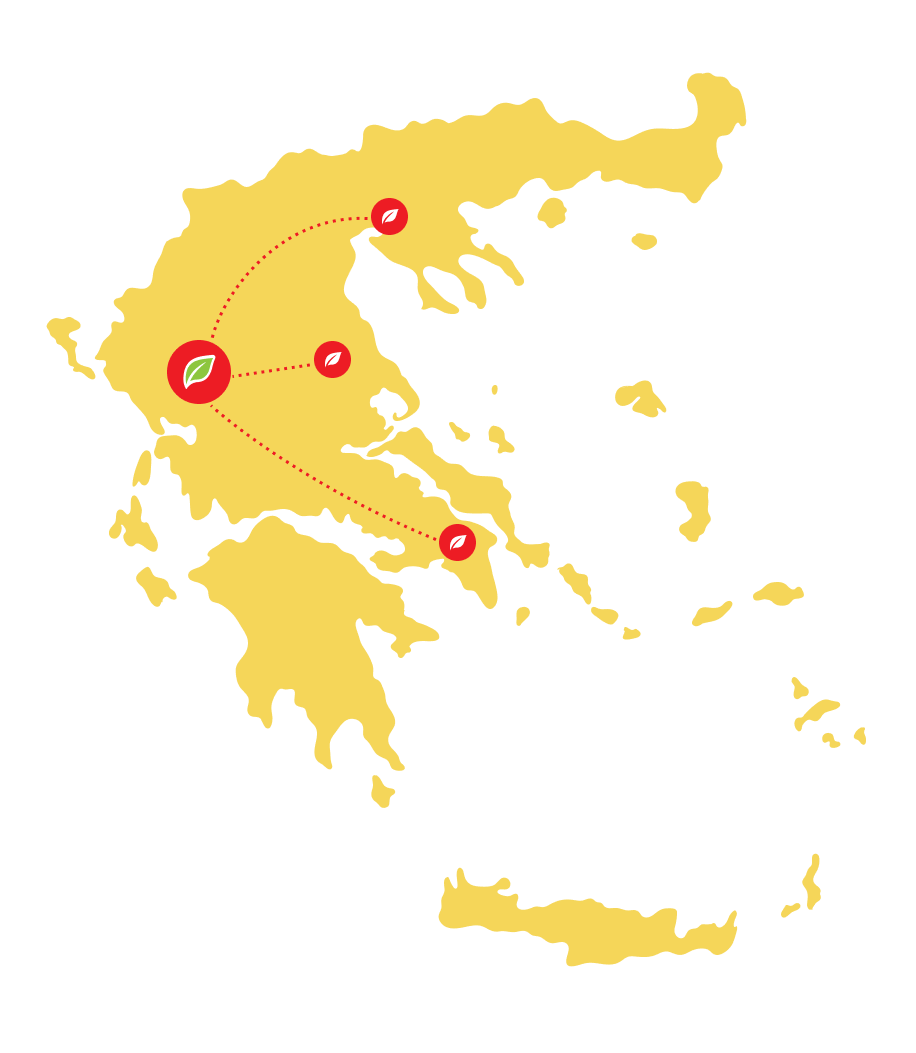

The distribution of Arta chickens is done through our privately-owned fleet of refrigerated trucks, ensuring direct delivery to customers. We maintain daily contact and communication with our customers to ensure we fully understand their preferences and requirements.

Our distribution network is strategically positioned to serve the entire country, including

Athens Branch (for the Attica region), Larissa Branch (for Thessaly), Thessaloniki Branch (for Northern Greece), Arta Headquarters (for Western Greece). This ensures fast and efficient delivery throughout Greece.